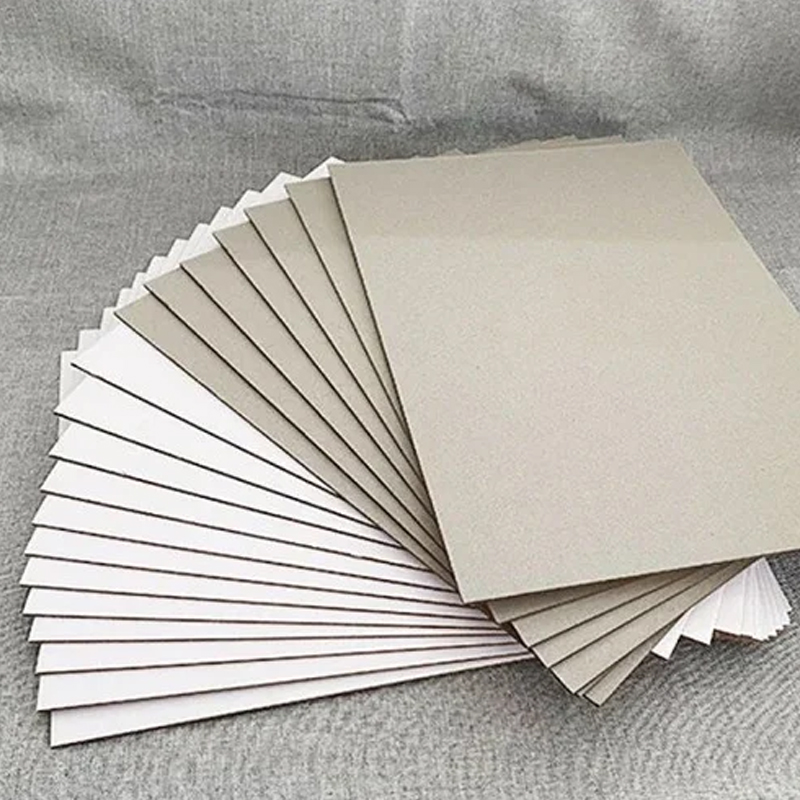

Duplex Board Grey and White Back

“Duplex Board Grey and White Back is a type of paperboard that is made with two different sides—one side is typically white, and the other side is grey. It is used primarily in packaging and for products where both printability and durability are important.

Key Characteristics of Duplex Board Grey and White Back:

Two-Tone Construction: White Side: The front side (white side) is usually smooth and coated, making it ideal for high-quality printing. This side is often used for displaying graphics, branding, product information, or artwork.

Grey Side: The reverse side is generally uncoated, and it has a greyish appearance, which is often due to the use of recycled or unbleached pulp in the core layers of the paperboard. This side is typically less smooth and not intended for high-quality printing but is still functional.

Composition: Duplex board is made from multiple layers of paperboard. The core is made from recycled fibers or lower-quality pulp, while the top layer is coated with higher-quality, bleached pulp to give it a smooth, white surface. This helps to keep production costs lower while still offering a visually appealing surface for printing on the white side.

Strength and Durability: Despite having a grey back, duplex board is strong and durable. It is commonly used for packaging products that require moderate protection, including lightweight or medium-weight items. The grey side often provides a solid, sturdy base for the packaging.

Eco-friendly: Since the core layer is often made from recycled fibers, duplex board is considered a more sustainable option compared to some other paperboard types. It is also recyclable and often used for products that require environmentally friendly packaging solutions.

Moisture Resistance: The grey side of duplex board might not have the same level of moisture resistance as other coated boards, but the white side can be treated to offer some level of resistance to moisture or grease.

Uses of Duplex Board Grey and White Back:

Packaging: Duplex board is commonly used in the packaging industry for products such as folding cartons, retail packaging, and boxes that do not require extreme strength but need to be visually appealing and cost-effective. It’s often used for food packaging, cosmetics, pharmaceutical products, and e-commerce packaging.

Retail and Consumer Goods: The white side of the duplex board makes it suitable for branding and product packaging where good printability is important. The grey back is practical for keeping production costs lower while still maintaining sufficient strength for handling and shipping.

Point-of-Sale (POS) Displays: Duplex board is also used for creating point-of-sale displays, which need to be sturdy enough to hold up in a retail environment, while the white surface provides a clean area for display graphics. Book Covers, Folders, and Inserts: The strong, rigid nature of duplex board makes it a good choice for the production of book covers, folders, and inserts, especially for retail or office supplies.

Summary: Duplex Board Grey and White Back is a versatile paperboard used primarily for packaging and printing. Its white front side allows for high-quality graphics and branding, while the grey back offers strength and cost-effectiveness. It is often used in retail, food packaging, and other consumer goods applications where both visual appeal and durability are needed at an affordable price point.

“